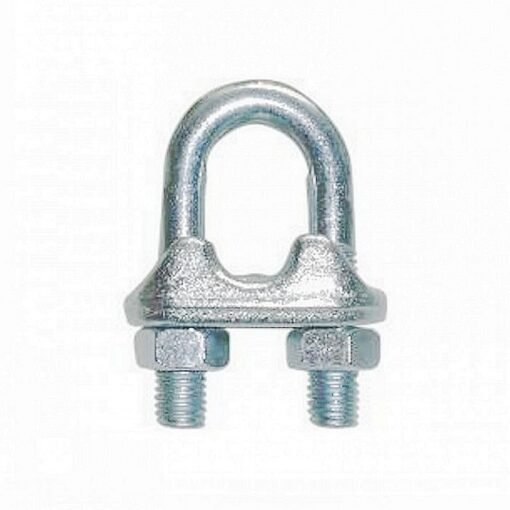

A 3 8 cable clamp refers to the diameter capacity of the cable clamp, indicating that it can effectively secure cables or wires with a diameter of up to 3/8 of an inch.

Cable clamps are used to organize and secure cables or wires in various applications to prevent tangling, damage, or interference.

- Light-duty clip, not for use in heavy-duty applications

- Galvanized finish for corrosion protection

- Meets Federal Specification FF-C-450, Type 1, Class 2

US Type Malleable cable clamp is produced according to Federal Specification FF-C-450 Type 1 Class 2. The clips can be zinc plated, hot-dip galvanized upon request. It’s also called wire rope clip, U Clip, U Clamp, U Bolt, which is used to form the wire rope loop or eye.

Key Features Of 3 8 Cable Clamp

1. Material: 3 8 cable clamp are typically made from malleable iron, which is a type of cast iron that has been heat-treated to increase its ductility and malleability. This material provides good strength and durability while maintaining some degree of flexibility.

2. U-Bolt Design: Like other wire rope clips, malleable wire rope clips have a U-bolt shape that allows the wire rope to pass through it.

3. Saddle Plate: The clips have a saddle plate that fits around the base of the U-bolt and sits on top of the wire rope.

4. Nuts: Two nuts are used to secure the U-bolt and saddle plate together, creating a tight grip on the wire rope.

The Installation

The installation of a 3 8 cable clamp follows a specific process to ensure proper performance and safety. Here are the general steps:

1. Positioning: Position the U-clamp around the wire rope where the loop or connection is desired.

2. Saddle Placement: Place the saddle plate on top of the wire rope, centered over the U-bolt.

3. Nuts Installation: Screw the two nuts onto the threaded ends of the U-bolt and tighten them alternately. Ensure they are tightened to the specified torque, following the manufacturer’s guidelines.

4. Check Tightness: After installation, check the tightness of the nuts regularly, especially during the initial period of use and periodically thereafter, to ensure they remain secure.

| SIZE MM |

A MM |

B MM |

C MM |

D IN |

E MM |

F MM |

G MM |

W/100PCS KGS |

| 1/8 |

11 |

14 |

14 |

1/4 |

10.8 |

22 |

20 |

1.54 |

| 3/16 |

14.5 |

15 |

16 |

1/4 |

13 |

26 |

24 |

2.5 |

| 1/4 |

17 |

18.5 |

20 |

5/16 |

15 |

32 |

31 |

5.3 |

| 5/16 |

18.3 |

20 |

22 |

5/16 |

16 |

35 |

34 |

5.9 |

| 3/8 |

22.5 |

22 |

27 |

3/8 |

22 |

40.5 |

41 |

11 |

| 7/16 |

24 |

23 |

30 |

3/8 |

22 |

43 |

42 |

11 |

| 1/2 |

27 |

26 |

35 |

7/16 |

23.3 |

49 |

53 |

18.5 |

| 9/16 |

30 |

26.5 |

40 |

1/2 |

27 |

52.5 |

54 |

25 |

| 5/8 |

33 |

28 |

40 |

1/2 |

28 |

57.5 |

59 |

28 |

| 3/4 |

34.5 |

32 |

42 |

9/16 |

34 |

61 |

68 |

35 |

| 7/8 |

41 |

37 |

46 |

5/8 |

38 |

71 |

78 |

53 |

| 1 |

45.5 |

42 |

55 |

5/8 |

43 |

77.5 |

87 |

66.6 |

Reviews

There are no reviews yet.