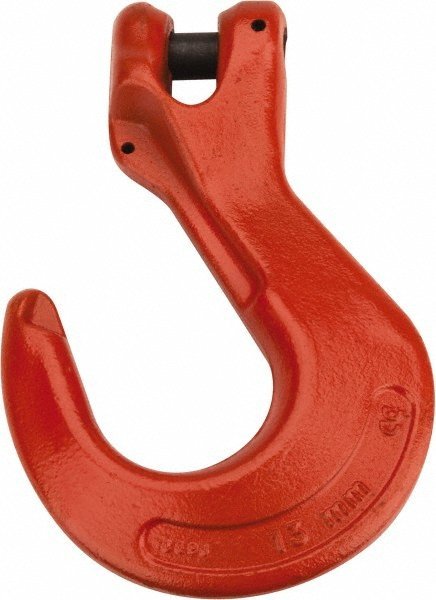

What Are Clevis Slip Hooks and How Are They Used?

Clevis slip hooks are versatile and widely used hardware components in rigging, towing, lifting, and load-securing applications. Known for their durability, ease of use, and secure connection, they play a critical role in industries such as transportation, construction, agriculture, and marine operations.

What Is a Clevis Slip Hook?

A clevis slip hook is a type of heavy-duty hook that combines two key features:

- Clevis Mount: A U-shaped bracket with two holes at the ends, designed to accept a pin, bolt, or shackle. This allows the hook to pivot or swivel, providing flexibility and reducing stress during lifting or pulling.

- Slip Hook Design: Unlike fixed hooks, a slip hook has an open throat that allows a chain or rope to slide through it easily—making it ideal for quick adjustments and tensioning.

These hooks are typically forged from high-strength carbon steel or alloy steel and are often heat-treated for added toughness. They may also feature a latch (in latching versions) for extra safety, though standard slip hooks rely on proper loading to stay secure.

How Does a Clevis Slip Hook Work?

The operation of a clevis slip hook is straightforward but highly effective:

- Connection: The chain (or rope) is passed through the open throat of the hook.

- Sliding Action: Because it’s a “slip” hook, the chain can move freely through the hook until tension is applied.

- Tension Locking: When force is applied—such as when tightening a chain with a binder—the chain naturally seats itself against the back of the hook. The angle of the load causes the chain to press firmly into the hook’s bowl, preventing it from slipping out under normal conditions.

- Pivoting Motion: Thanks to the clevis mount, the entire hook can rotate or swivel around the pin or shackle. This movement helps align the load properly and reduces side-loading or twisting that could weaken the connection.

This combination of sliding adjustability and rotational flexibility makes clevis slip hooks especially useful in dynamic environments where load angles change or where frequent re-rigging is needed.

Common Applications

- Securing cargo on flatbed trucks using transport chains.

- Attaching winch cables or tow straps in recovery operations.

- Rigging in construction for lifting materials.

- Agricultural equipment hitching and trailer connections.

- Marine tie-downs and dock rigging.

Safety Considerations

- Always check the Working Load Limit (WLL) stamped on the hook and never exceed it.

- Inspect for cracks, deformation, or excessive wear before each use.

- Ensure the clevis pin or shackle is properly secured and rated for the same load.

- Avoid side-loading the hook, as this can cause bending or failure.

- Use latching versions in high-vibration or overhead lifting scenarios for added security.

Reviews

There are no reviews yet.