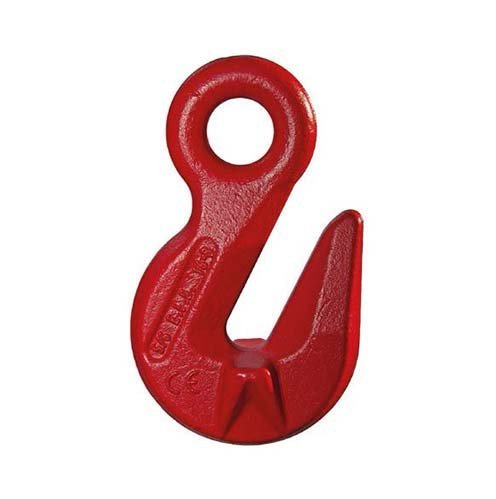

What Is an Eye Grab Hook and How Does It Work?

An eye grab hook is a specialized type of load-securing hardware commonly used in transportation, towing, rigging, and industrial applications. Combining the strength of a forged steel hook with the versatility of an integrated eye, this component offers a secure, reliable, and easy-to-use connection point for chains, cables, or tie-down systems.

What Is an Eye Grab Hook?

An eye grab hook features two main parts in a single forged unit:

- The Hook End: Designed with a wide, open throat that “grabs” a link of a transport chain. Unlike standard hooks, the grab hook is shaped to wrap around the side of a chain link and lock into place under tension.

- The Eye End: A closed loop (or “eye”) at the opposite end, used to connect to anchor points such as D-rings, shackles, trailer frames, or other rigging hardware.

These hooks are typically made from high-grade carbon or alloy steel, heat-treated for maximum strength and durability, and often stamped with a Working Load Limit (WLL) for safety compliance.

How Does an Eye Grab Hook Work?

The eye grab hook operates through a simple yet effective mechanical principle:

- Attachment to Chain: The open throat of the hook is placed over the side of a chain link (not through the link, but around its outer edge).

- Tension Engagement: When the chain is tightened—using a lever binder, ratchet, or winch—the load pulls the chain link firmly against the inner curve (bowl) of the hook.

- Self-Locking Action: As tension increases, the chain naturally seats deeper into the hook, preventing it from slipping out during transit. The hook’s geometry ensures that the more force applied, the tighter the grip becomes.

- Connection via the Eye: The eye end is secured to a fixed anchor point (like a trailer’s stake pocket or frame) using a shackle, bolt, or pin. This creates a complete, load-bearing loop from anchor → eye → hook → chain → cargo.

Some eye grab hooks also come with a safety latch over the throat to prevent accidental disengagement during vibration or sudden shifts—especially important in overhead lifting or high-movement environments.

Common Uses

- Securing heavy machinery, vehicles, or equipment on flatbed trailers.

- Connecting transport chains to trailer anchor points.

- Agricultural and construction hauling.

- Marine and industrial rigging setups.

Safety Tips

- Always verify the Working Load Limit (WLL) and never exceed it.

- Inspect the hook regularly for cracks, deformation, or wear—especially at the throat and eye.

- Ensure the chain link is properly seated in the hook before applying full tension.

- Use latched versions when working in high-vibration or critical lifting scenarios.

- Never use a damaged or bent hook—even minor defects can lead to catastrophic failure.

Reviews

There are no reviews yet.