What Is an Eye Hoist Hook and How Is It Used?

In lifting, rigging, and material handling operations, precision, strength, and safety are paramount. One of the most essential—and often overlooked—components in these systems is the eye hoist hook. Designed for reliable load attachment in overhead lifting applications, this specialized hook plays a critical role in ensuring smooth, secure, and compliant lifting operations across industries like construction, manufacturing, warehousing, and shipyards.

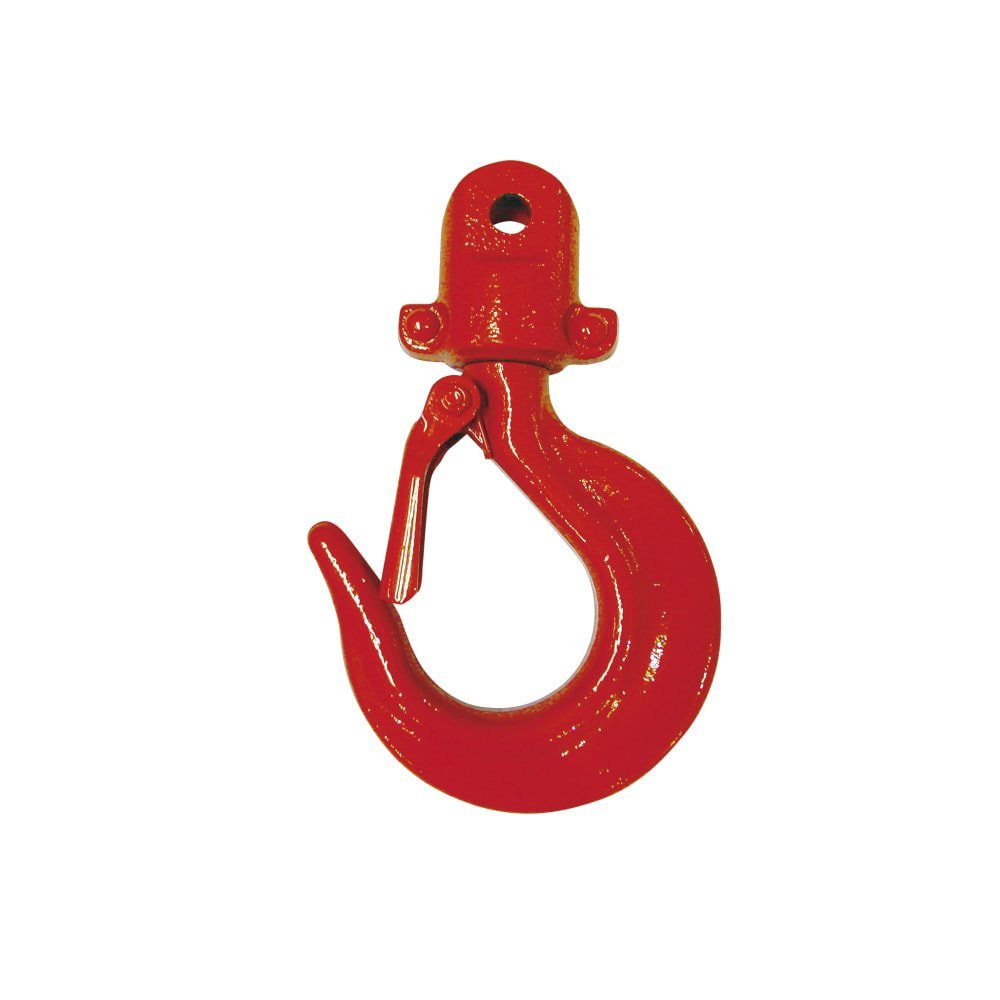

What Is an Eye Hoist Hook?

An eye hoist hook is a forged steel lifting hook featuring a closed eye at one end and a curved, throat-equipped hook at the other. Unlike standard hooks, hoist hooks are engineered specifically for vertical lifting and are commonly used as the lower attachment point on chain hoists, wire rope slings, or crane systems.

Key characteristics include:

- Forged from high-grade alloy steel for maximum strength and ductility.

- Heat-treated and proof-tested to meet international safety standards (such as ASME B30.10 or EN 1677).

- Stamped with a Working Load Limit (WLL) and often color-coded for quick identification.

- Wide, smooth throat to reduce wear on slings or chains and allow easy rotation under load.

The eye provides a secure connection point to the hoist mechanism, while the hook safely holds the load—whether it’s a sling, shackle, or lifting attachment.

How Does an Eye Hoist Hook Work?

The eye hoist hook functions as the critical interface between the lifting device and the load:

- Connection to Hoist: The eye end is attached directly to the bottom block of a chain hoist, electric hoist, or crane hook—often via a swivel or shackle to allow rotation.

- Load Attachment: The hook end receives the top fitting of the load—such as a sling, master link, or lifting eye on the cargo.

- Load Distribution: When lifted, the force is channeled through the hook’s bowl (the curved inner base), which is the strongest part of the design. The hook’s geometry ensures even stress distribution and minimizes the risk of slippage.

- Safety Monitoring: Most eye hoist hooks include a safety latch (either spring-loaded or screw-type) that prevents the load from accidentally slipping out of the throat—especially during movement or sudden stops.

Importantly, hoist hooks are designed to rotate freely under load, which helps prevent twisting of slings and ensures the load remains stable during lifting and positioning.

Common Applications

- Overhead cranes and gantry systems in factories and warehouses.

- Chain and electric hoists for maintenance or assembly lines.

- Shipyard and port operations for loading/unloading cargo.

- Construction sites for lifting steel beams, precast concrete, or machinery.

- Aircraft hangars and automotive repair shops for engine or component removal.

Safety & Inspection Guidelines

- Never exceed the Working Load Limit (WLL) marked on the hook.

- Inspect before each use for:

- Cracks, nicks, or deformation (especially in the throat or saddle).

- Excessive wear (more than 10% of original cross-section).

- A distorted or stretched hook opening (indicating overload).

- A malfunctioning or missing safety latch.

- Replace immediately if the hook shows signs of damage or has been shock-loaded.

- Ensure the latch is always closed and functioning properly during lifting.

Reviews

There are no reviews yet.