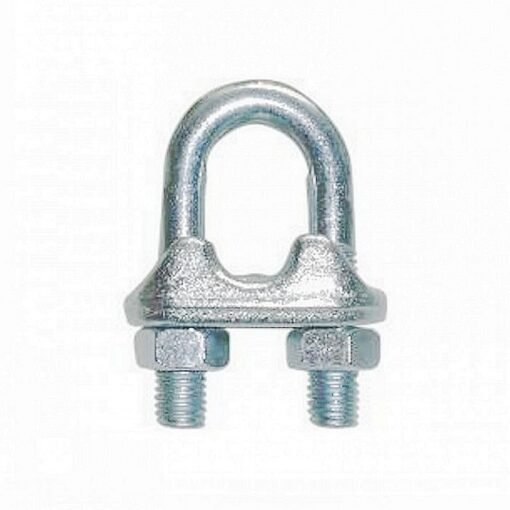

Stainless Steel Cable Clamps DIN 741 – Corrosion-Resistant, High-Strength Wire Rope Terminations

Key Features:

- Full Stainless Steel Construction: Both U-bolt and saddle are made from stainless steel—no malleable iron or plated components—ensuring long-term integrity in corrosive environments.

- DIN 741 Compliance: Meets strict European dimensional and performance standards for wire rope clips, guaranteeing consistent quality and load-holding capability.

- Secure Termination: Designed to firmly clamp the “live end” of wire rope, creating stable eye loops or end fixings that resist slippage under load.

- Smooth, Rounded Profile: Minimizes damage to wire rope strands during installation and use.

- Permanent Markings: Clearly stamped with size and standard reference for easy identification and traceability.

Common Applications:

- Marine rigging, mooring lines, and sailboat hardware

- Food & beverage processing equipment

- Chemical and pharmaceutical machinery

- Architectural cable railings and tension systems

- Outdoor lifting and suspension systems in coastal or industrial zones

Installation Best Practices:

- Always place the saddle on the live (load-bearing) end of the rope—“Never saddle a dead horse.”

- Use the correct number of clamps per wire rope diameter (typically 2–3, spaced properly).

- Torque bolts evenly and re-tighten after initial load application.

- Inspect regularly for wear, deformation, or loosening.

⚠️ Note: While highly durable, stainless steel clamps have lower tensile strength than carbon steel equivalents—ensure they are rated for your specific load requirements.

When corrosion resistance and reliability are critical—trust DIN 741 Stainless Steel Cable Clamps for performance that lasts.

| SIZE MM | A MM | B MM | C MM | D MM | E MM | F MM | G MM | W/100PCS KGS |

| 3MM | M4 | 21 | 10 | 10 | 9 | 12 | 16.6 | 1.4 |

| 5MM | M5 | 23 | 10 | 11 | 11 | 13 | 19.65 | 1.5 |

| 6MM | M5 | 26 | 11 | 12 | 13 | 15 | 23.65 | 2.1 |

| 8MM | M6 | 30 | 15 | 14 | 16 | 19 | 28.85 | 4.1 |

| 10MM | M8 | 34 | 17 | 18 | 19 | 22 | 35 | 6.8 |

| 11MM | M8 | 36 | 18 | 19 | 20 | 22 | 37 | 7.2 |

| 13MM | M10 | 40 | 21 | 23 | 24 | 30 | 46.24 | 13 |

| 14MM | M10 | 44 | 22 | 23 | 25 | 30 | 48.24 | 13.5 |

| 16MM | M12 | 50 | 26 | 26 | 29 | 33 | 52.5 | 21 |

| 19MM | M12 | 54 | 30 | 29 | 32 | 38 | 64.5 | 28 |

| 22MM | M14 | 61 | 34 | 33 | 37 | 44 | 72.5 | 40 |

| 26MM | M14 | 65 | 37 | 35 | 41 | 45 | 82.5 | 44 |

| 30MM | M16 | 74 | 43 | 37 | 48 | 50 | 95.6 | 66 |

| 34MM | M16 | 80 | 50 | 42 | 52 | 55 | 105.6 | 85 |

| 40MM | M16 | 88 | 55 | 45 | 58 | 60 | 125.6 | 104 |

| 40/50MM | M20 | 105 | 63 | 52 | 69 | 98 | 176 | 200 |

NOTE:

It’s essential to follow the manufacturer’s instructions and guidelines when installing wire rope clips to ensure proper usage and safety. Incorrect installation can compromise the strength and reliability of the connection, leading to potential accidents.

Reviews

There are no reviews yet.